“Leave Bobby Alone”: Power-Hungry Boss Won’t Listen, Messes Around With Key Worker, Gets Fired

Oftentimes, one person is enough to interrupt the workflow of the company or bring all processes to a halt. And whether intentional or not, their actions can result in significant losses.

That’s what happened with this redditor’s friend, “Bobby”, whose malicious compliance led to a slowed pace of operations at the workplace and thousands of dollars in losses; all because of their aggravating superior. Scroll down to find the full story below.

Below you will also find Bored Panda’s interview with Dr. Ronald Riggio, Professor of Leadership and Organizational Psychology at Claremont McKenna College in Claremont, California, who was kind enough to answer a few of our questions.

In a workplace that operates like a well-oiled machine, every employee matters

Image credits: monkeybusiness / Envato (not the actual photo)

This employee’s malicious compliance cost his company thousands of dollars, all thanks to his new superior

Image credits: FoToArtist_1 / Envato (not the actual photo)

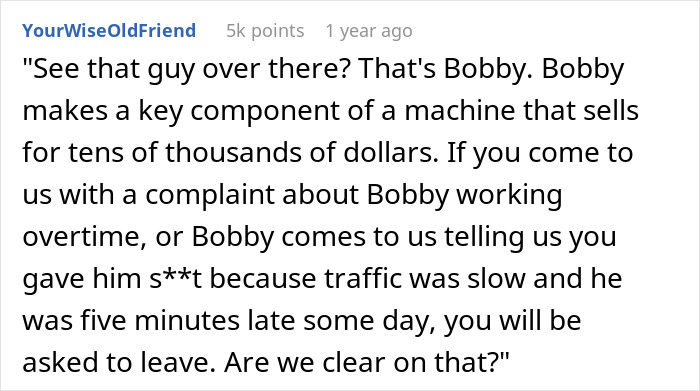

Image credits: fire_me_anytime

Bobby didn’t get along well with the new foreman

Image credits: picryl (not the actual photo)

Few people would likely argue the importance of rules and regulations at work. They are necessary in order to make sure that everything runs smoothly and everyone involved is well-aware of both their rights and responsibilities. But in order for rules to work, there shouldn’t be exceptions in regards to who has to abide by them.

In the OP’s story, the new foreman, who was said to be a jerk to the redditor’s friend, Bobby, was seemingly quite keen on following workplace rules. That’s why when Bobby came to work 10 minutes late, the superior was holding a demerit slip, as it was the second time the employee had clocked in late in the last 14 days; he didn’t care much that the first time Bobby was just one minute late.

While it’s true that being 10 minutes late is likely a violation of workplace rules, penalizing an employee for clocking in just one minute after the start of their working hours likely balances on the brink of micromanaging. Unsurprisingly, such an overly attentive management style is considered to be the main red flag signaling a toxic workplace, according to a poll carried out by Monster.

Another survey found that roughly four-in-five employed people have experienced micromanaging and nearly 70% have considered changing jobs because of it. While Bobby didn’t quit his job because of the new foreman, he realized that two can play this game and decided to unconditionally stick to the rules, too, which meant no more working overtime.

“There needs to be give and take on both sides—with both the employer and the employee adhering to the ‘contract’ they have about promptness, overtime policy, and whether staying late can compensate for a late start,” Dr. Ronald Riggio told Bored Panda, adding that trying to work out some sort of a flexible schedule, if need be, can also be a good idea if appropriate under the given circumstances.

Employee-supervisor relationship can significantly influence the former’s job performance as well as their overall well-being

The reason it’s important to try and find a solution to the problem is that according to the expert, the most common source of workplace stress comes from interpersonal issues or conflict, either in relationships with other team members, or in the supervisor-employee relationship.

“Work stress can lead to diminished performance, a lack of commitment to the job and to the organization and can result in voluntary absenteeism—calling in sick when you’re not—and increased turnover; of course, a worker’s stress can spillover to their home life and to their health and well-being, as well.

“So, the supervisor-employee relationship is critically important for having good work outcomes,” he said, adding that leaders and supervisors need to be aware of how their behavior is impacting employees and be a source of support instead of stress.

Prof. Riggio also emphasized that it’s important to show the hard-working employees that they are appreciated and that their effort does not go unnoticed. “To motivate workers, it is imperative that supervisors reward and recognize employees for their efforts and their good work. Many workers are willing to go ‘above and beyond’ in terms of their performance if they feel that they are appreciated.”

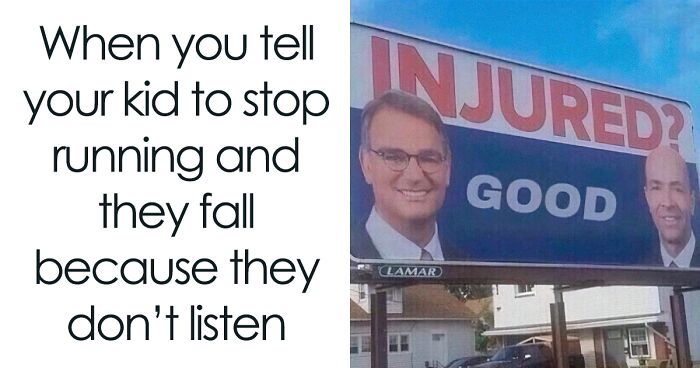

Quite a few people nowadays seem to put in unpaid overtime

Image credits: Rodeo Software / Pexels (not the actual photo)

It’s safe to assume that Bobby is far from the only one who has worked overtime in their careers. Ciphr’s research found that employees from 35 to 44 years of age are the most likely to work unpaid overtime, and those from 25 to 34 accumulate the most hours of such additional time spent at work, averaging 3.5 hours per week. It also found that on a regular week, the number of people working unpaid overtime is twice higher than those who get paid for it.

According to Clockify, despite overtime being regulated by different laws in most countries, research found that as many as one in ten employees have worked an extra day of unpaid overtime every week in 2021.

Be that as it may, the number of hours people spend working in general has reportedly decreased over the years, as people became more and more productive. Clockify found that employed individuals now work roughly 20-30 hours less each week compared to the 19th century. According to their data, the average work hours in developed countries went from 3000 hours per year in 1870 to 1500-2000 hours per year by 1990.

Clockify also revealed that nowadays, in Europe, the Netherlands seem to be the country where people work the least hours, adding up to roughly 1627 hours per year (roughly 31 per week), while Turkey is on the other end of the scale, as that’s where people spend 2256 hours a year (43 per week) at work.

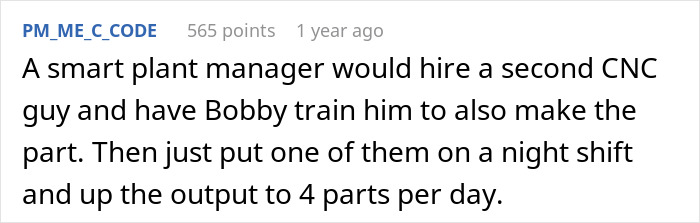

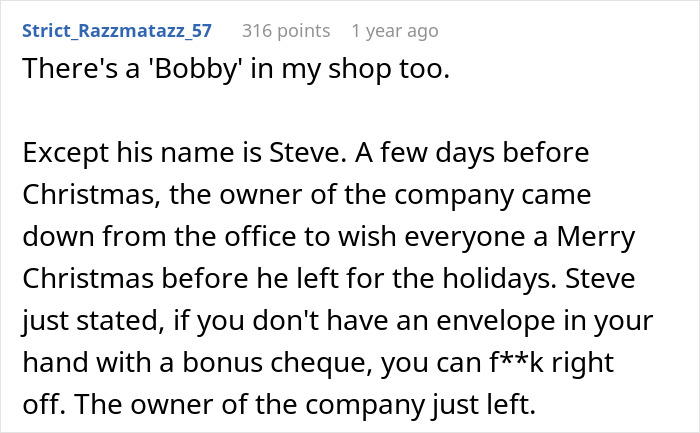

The OP didn’t specify where in the world Bobby was based, however, one thing was made clear—the number of hours he spent at work decreased when the new foreman started intervening. Be that as it may, it wasn’t the number of hours or the foreman’s behavior that fellow netizens seemed to be interested in the most; many seemed to focus most on how critical Bobby was for the company. They shared their views in the comments section.

Fellow netizens shared their thoughts and stories in the comments

Poll Question

Thanks! Check out the results:

All sounds a bit unsatisfactory. If this was such a key part of the process and nobody else could do the job, what happened if he was sick or on vacation? In any case, the Union, and any foreman/supervisor, worth their salt, would have been pushing hard to get a second operator on the team, so they could cover each other, and be able to perform other tasks without leaving the CNC machine unsupervised.

Maybe it would be nice to work for a union. I never get to use my pto cause my job can't get by without me. Its frustrating at times.

Load More Replies...Worked for a company that got a large contract to adjust a part for a large car manufacturer, it required some stripping of the vehicle, removing the part that if you got the order of operations wrong it became a pain in the a*s with the airbag systems, adjust the part and then put it all back together. I did the stripping and rebuilding of vehicles all around the U.K., I was the only member of staff who knew the process. After a month of me doing the job (and making sure I was fully au fait with how it worked) my bosses sent others with me, one at a time, to learn the process. No one was mission critical. We carried two or three adjusted parts with us and customers were never left without a car. It’s really not hard to manage a process correctly, if your managers do it right it actually ends up making everyone appreciate each others skills a bit more, end result? A happier ship.

All sounds a bit unsatisfactory. If this was such a key part of the process and nobody else could do the job, what happened if he was sick or on vacation? In any case, the Union, and any foreman/supervisor, worth their salt, would have been pushing hard to get a second operator on the team, so they could cover each other, and be able to perform other tasks without leaving the CNC machine unsupervised.

Maybe it would be nice to work for a union. I never get to use my pto cause my job can't get by without me. Its frustrating at times.

Load More Replies...Worked for a company that got a large contract to adjust a part for a large car manufacturer, it required some stripping of the vehicle, removing the part that if you got the order of operations wrong it became a pain in the a*s with the airbag systems, adjust the part and then put it all back together. I did the stripping and rebuilding of vehicles all around the U.K., I was the only member of staff who knew the process. After a month of me doing the job (and making sure I was fully au fait with how it worked) my bosses sent others with me, one at a time, to learn the process. No one was mission critical. We carried two or three adjusted parts with us and customers were never left without a car. It’s really not hard to manage a process correctly, if your managers do it right it actually ends up making everyone appreciate each others skills a bit more, end result? A happier ship.

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

54

27