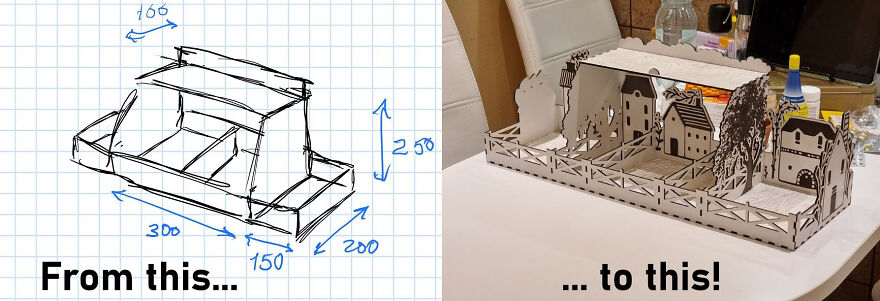

Instead Of Making Another Boring DIY Box, I Added A Little Magic (And Lasers) To It

Hello Pandas!

Here’s the story of my DIY project. I believe it may be helpful and inspire people to create designs for home with the soul.

Please enjoy and find me on Twitter!

Made with @LightBurnLaser & #endurancelasers (10W module with G7 lenses and v2 air assist nozzle), plus some cheap Chinese laser engraver with DIY air assist system.

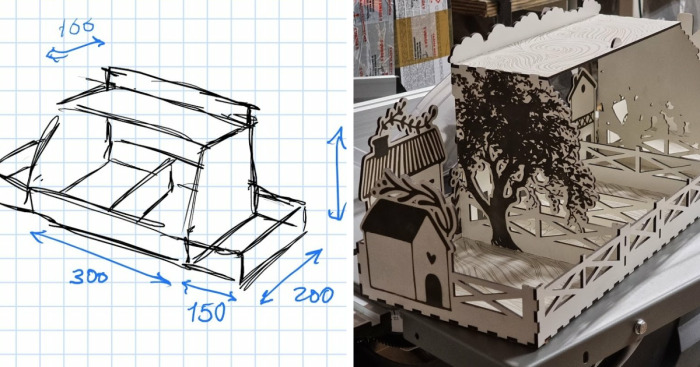

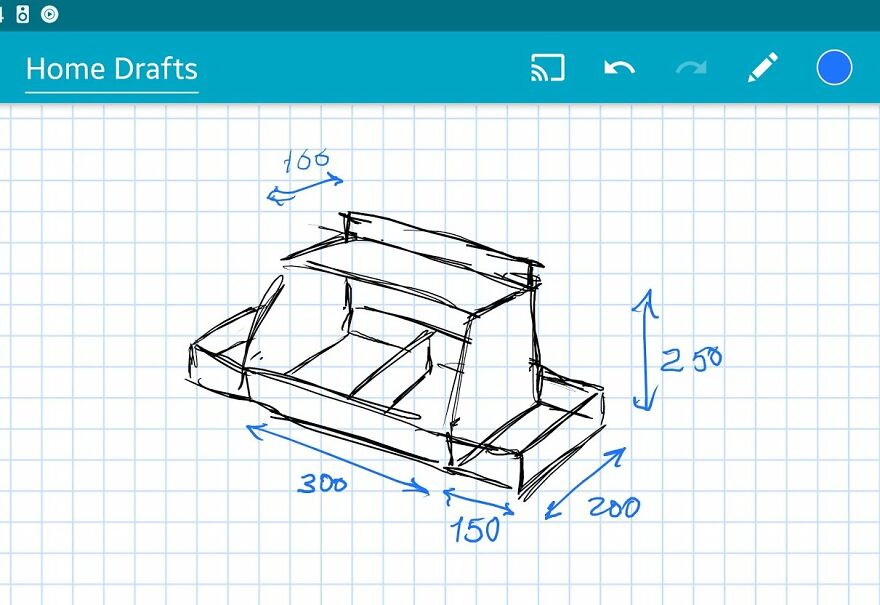

So, step 1, the sketch!

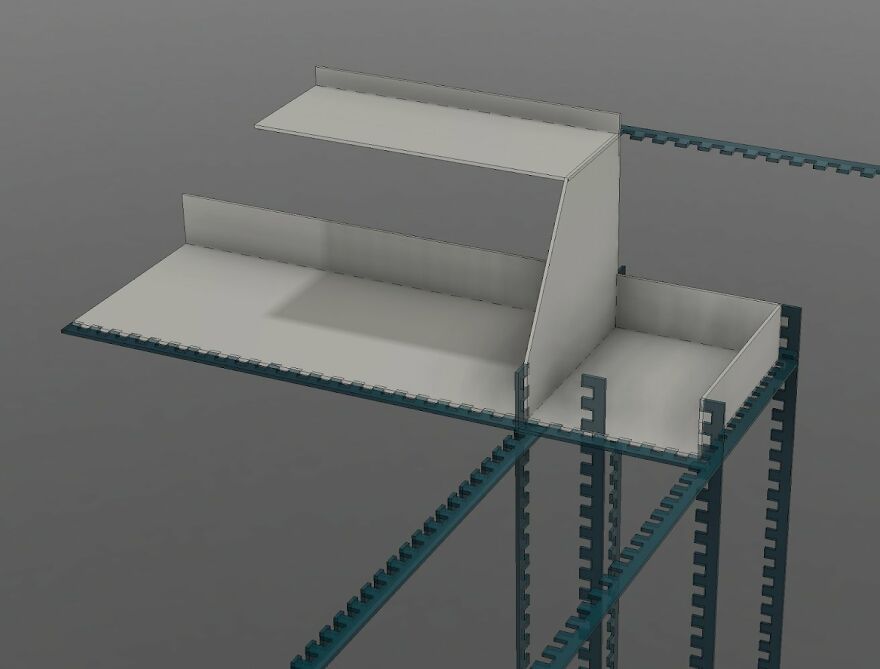

Step 2,fusion360, a box with base dimensions and shape

I never created models for laser cutting (and never learned how to build), so I tried to develop my own approach as this is the first but not the last model I will make.

Step 3, assembly planning

I’ve been thinking a lot about making the groove cuts and making them parametric, so you can edit all at once and make the process repeatable in the future. I think I found a way.

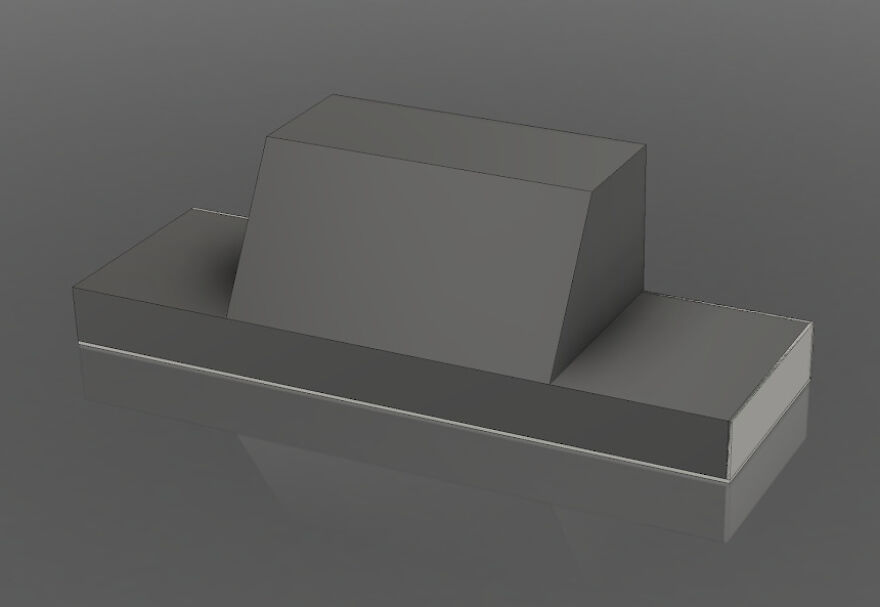

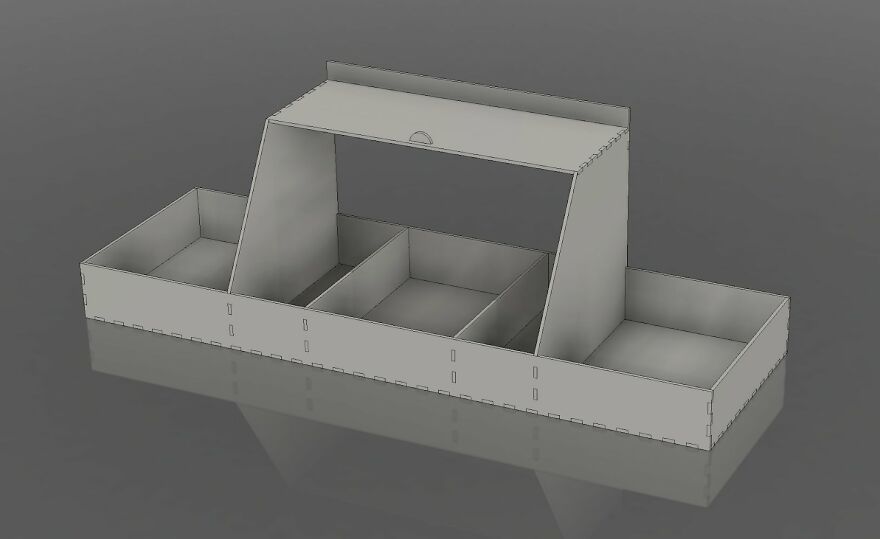

Step 4, final base model look

All the cuts are in place, the has-been model assembled. I had to change the design and dimensions a bit, but this was to be expected. And although the model uses expressions it was not so difficult to adjust it.

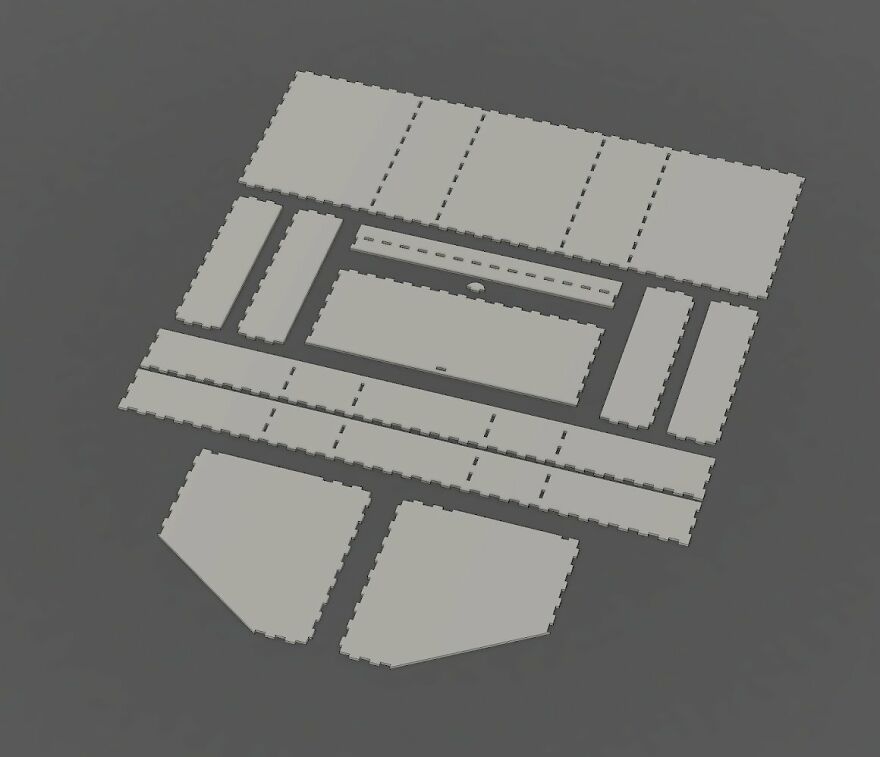

Step 5, sketch export

I used Shaper Utilities to export 3d models layout as a 2d vector sketch. Now it is ready for some magic.

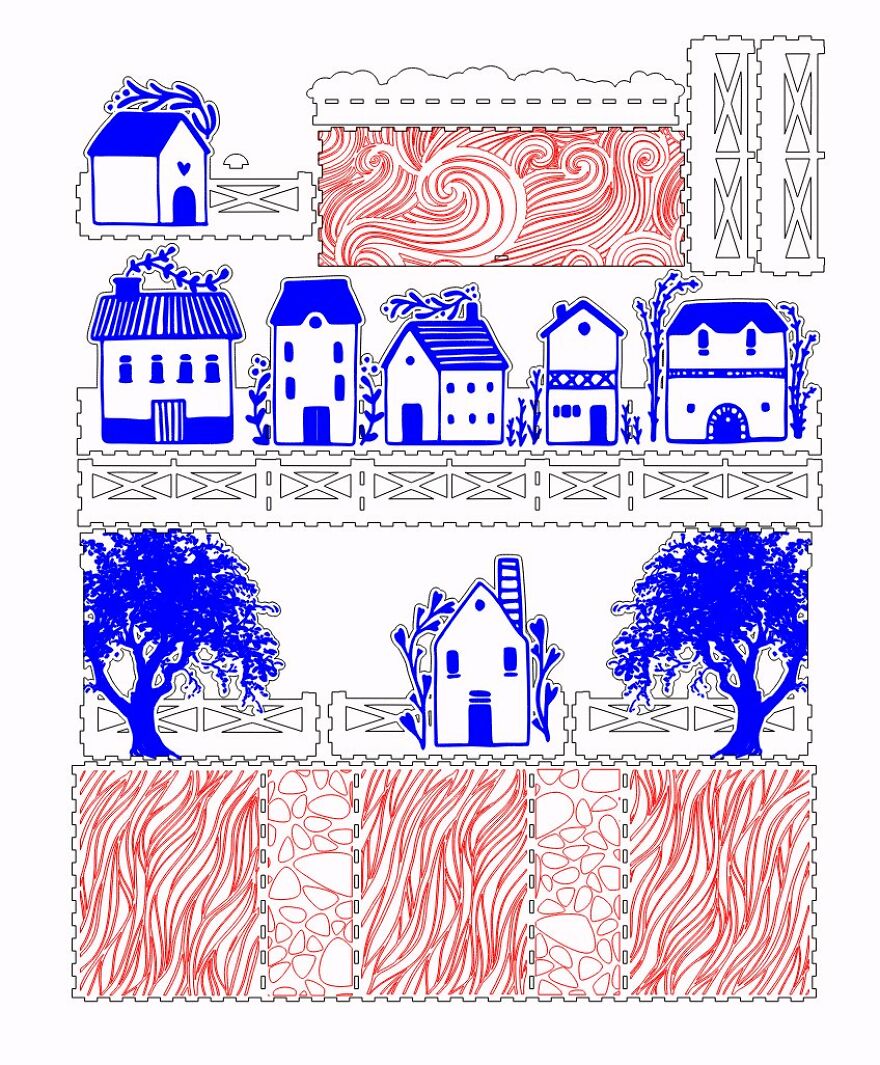

Step 6, the MAGIC!

I googled for some images to make the box more attractive. I used low-quality raster images, so I scaled them up and vectorized them. And after a few hours, I prepared a nice themed scheme for cutting and engraving.

Step 7, the test

I set the engraving and cutting parameters and did a test run. And almost immediately discovered that the MDF is quite fragile, and I need to be careful when assembling it.

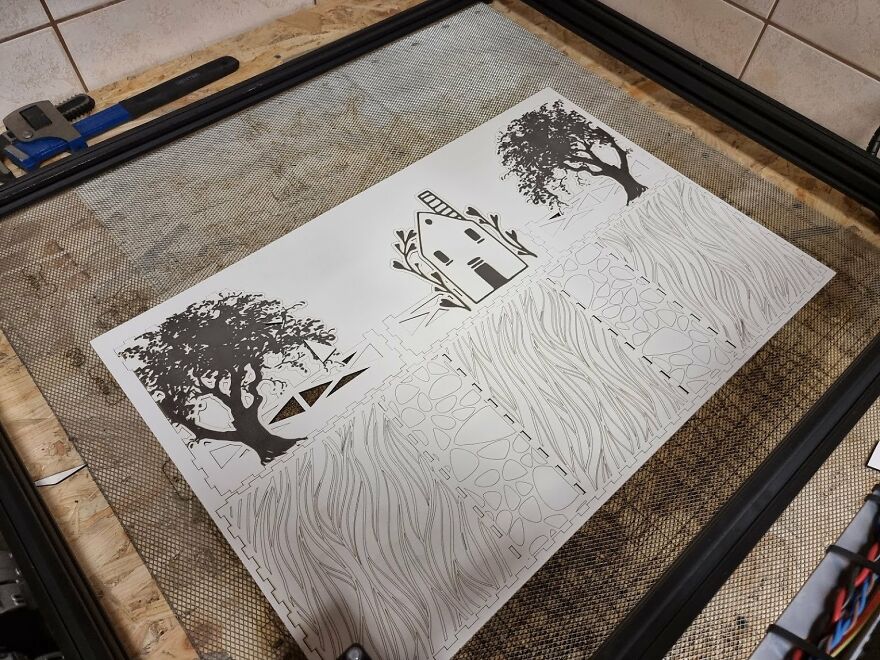

Step 8, cutting, part one of two

I chose a double-sided white laminated MDF with a thickness of 3mm and a size of 600x400mm per sheet. So I had to split the model into two parts. And here’s the first part.

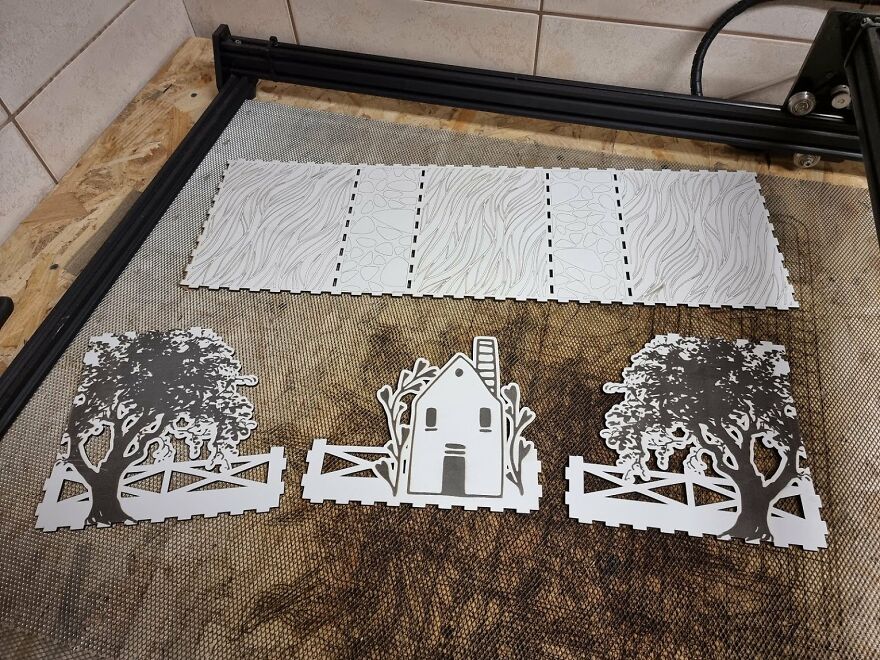

Step 9, cutting, part two of two

On the second sheet, I make some minor changes to the final design.

Diode laser at work with DIY air assist unit

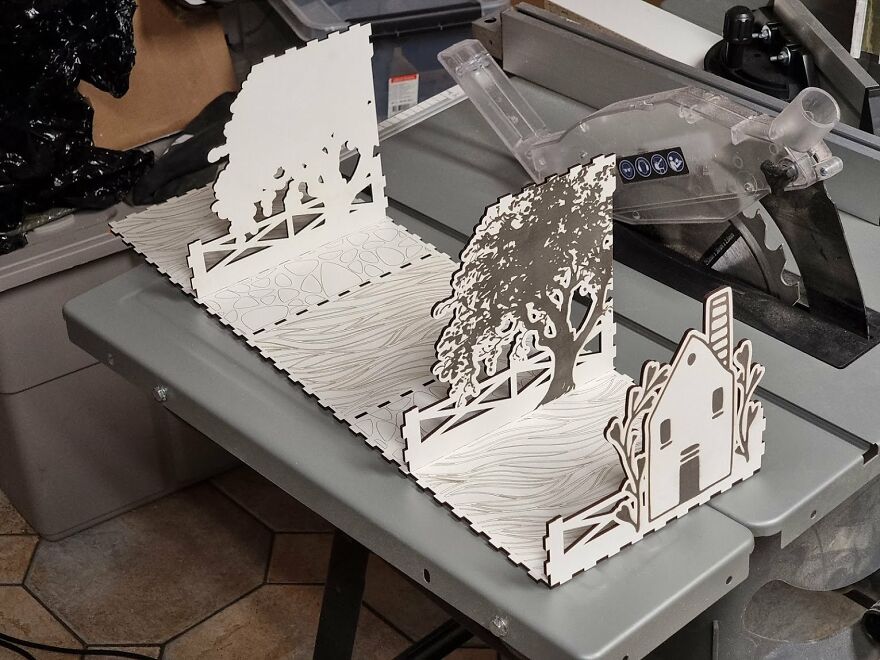

Step 10, assembly!

A couple of drops of white glue and simple parts attaching one by one. The easiest and the most enjoyable part of the job.

And finally, the RESULT!

880views

Share on Facebook

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

19

0