“‘You Can’t Work Overtime Even Though We’re 3000 Behind.’ OK, I Won’t, Then”

Few people know that initially there should have been not seven, but eight mortal sins, and the eighth should have been irresponsibility. But at the last moment, someone who compiled the list relied on another person – and now, we have what we have. At the same time, almost more people have suffered because of simple irresponsibility than because of all other sins combined.

But seriously, each of us has a couple of stories about how our or someone else’s irresponsibility led to serious problems – be it business, study or personal life. Best of all, of course, is someone else’s irresponsibility than one’s own – after all, the same list of mortal sins also contains pride.

Well, here’s an example of such a story about someone else’s irresponsibility, perfectly seasoned with blatant incompetence. Everything we love! Indeed, having appeared just one day ago in the Reddit Malicious Compliance community, the original post has already gained about 7.2K upvotes and more than 250 different comments.

More info: Reddit

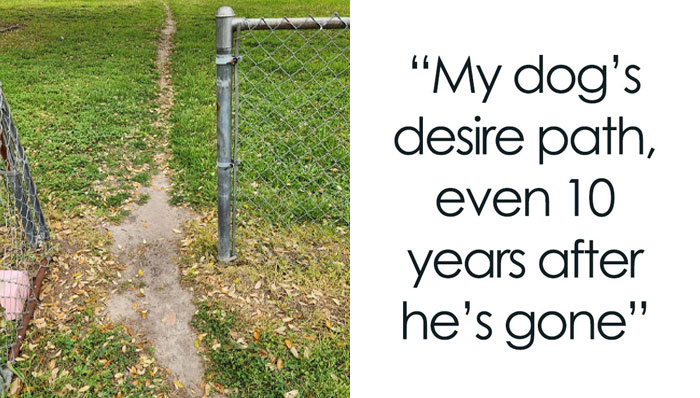

The Original poster worked at a big plant and their main job was to calibrate tools and robots

Image credits: PEO ACWA (not the actual image )

So, the Original Poster worked for a large company where their main job was to calibrate tools and robots at the plant to customer specifications. The main problem of their job, in addition to the huge number of customization tools, was that any non-compliance with the requirements of the client specification allowed the customer to pull out of their contracts with no legal ramifications.

Image credits: u/B1llyTheG0at

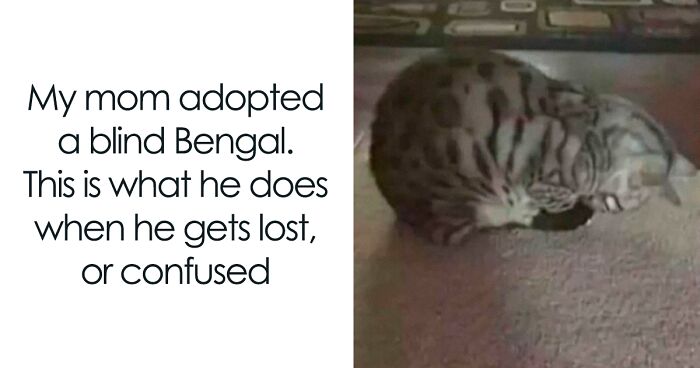

The OP’s boss was hired literally off the street and turned out to be a rather irresponsible person

In other words, the OP’s and several of their colleagues’ job was perhaps the most important in the entire plant. True, the management definitely did not agree with this, and one fine day also overcomplicated the OP’s work by hiring the boss of their department literally off the street, who turned out to be not only incompetent, but also irresponsible.

Image credits: u/B1llyTheG0at

As a result, due to inconsistency with the workers on the plant lines, the number of uncalibrated tools constantly increased – and the boss, who was regularly asked by the OP and their colleagues to solve the interaction issues, just kept telling them to work around it.

Image credits: Moreno Ted (not the actual image )

The boss didn’t care about overdue calibrations and it looked like a ticking time bomb, according to the OP

After some time, approximately six thousand machines and robots that were subject to calibration were actually calibrated, and three thousand remained overdue. In the OP’s own words, it was a ticking time bomb planted under the entire company – but practically no one cared.

Image credits: u/B1llyTheG0at

One day, an important client told the company that they would come on Monday to check the machines assigned to their tasks

One fine day, one of the company’s important customers called and warned that they would come with an inspection the following Monday. The OP realized that this was going to be a huge problem, since almost all the robots and tools involved in this client’s tasks were out of date.

Image credits: u/B1llyTheG0at

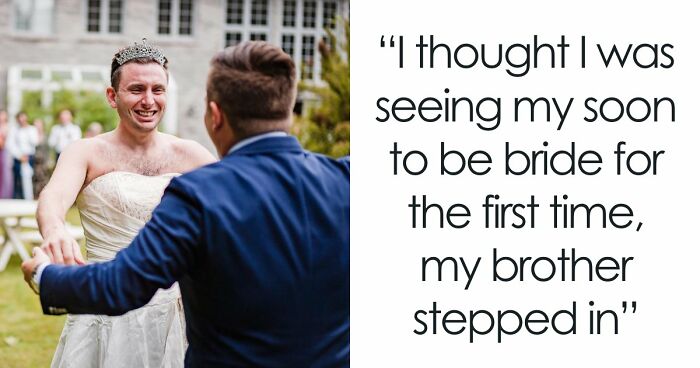

The OP offered to work over the weekend to fix everything, but their boss rejected this idea

The OP suggested to the boss that they could go out to work over the weekend to calibrate at least some of the client’s machines before the inspection and avoid a major conflict. To this, the boss demanded a complete list of tools that the OP planned to deal with during their overtime work. The engineer reasonably objected that they just could not do this, because they did not know in advance what they would have to replace and when.

Image credits: u/B1llyTheG0at

The OP said that they could make such a list either during the weekend or on Monday morning. The boss didn’t like this idea for some reason, and they forbade the OP to show up for work on the weekend. They shrugged their shoulders and maliciously complied… What was there more to be done?

Image credits: u/B1llyTheG0at

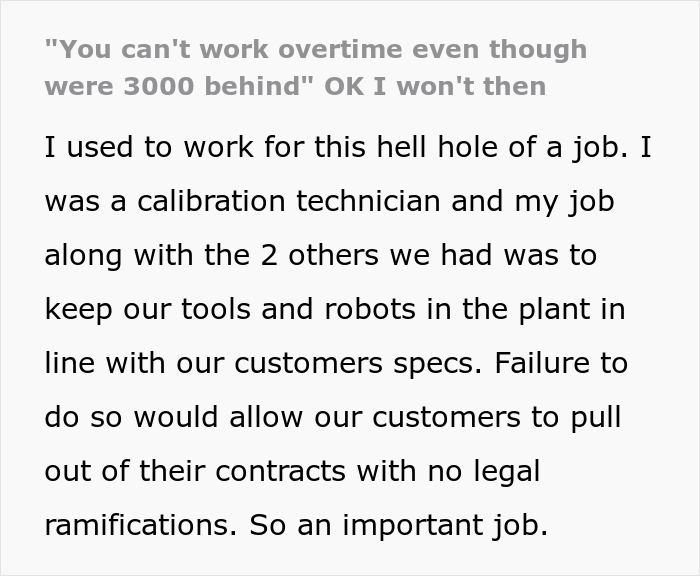

Everything ended up with a huge scandal as all the client’s machines’ calibrations turned out to be overdue by 4 months

On Monday, the scandal predicted by the OP erupted – the client came, saw that almost all of their tools had not been calibrated for the last four months, immediately canceled the contract and recalled all the products for the same timespan. The management, of course, criticized the OP’s department heavily, and the engineer themselves looked at their boss, laughed – and quit.

Imagecredits: Micah Elizabeth Scott (not the actual image )

Later, according to the OP, the angry client signed a new contract, much less profitable for the OP’s former company. Moreover, apparently, the client told other customers about this particular story, so that the reputation of the plant was critically undermined – and after another year, they ended up selling the whole place.

People in the comments agreed that this situation looks really common for many businesses

According to people in the comments, preparedness costs and complacency costs much more, and this is true as hell. One commenter admitted that they only make wooden home decor, but constantly check their saws’ angles each time before use. However, the larger the size of the business, the more often, alas, one has to deal with huge irresponsibility.

As can be seen from the comments, such cases, unfortunately, are not uncommon. For example, one of the commenters’ company wants stuff done fast and says to just get it done, cut corners if you can. No time to do it right, but they have to find time to redo it when the customer sends it back. As the commenter themselves admit, luckily it’s only house windows and doors, nothing life-threatening. One can only hope that different rules really apply in the production of something life-critical.

We do think you too have a similar story of simple human irresponsibility which ended up causing a business serious problems, so comments are welcome as always. Or you can just write what you think about this very narrative.

And here’s me keeping a Windows 3.1 box running because it’s the only thing that can connect to and calibrate a piece of kit (it’s a very old piece of kit and modern hardware will not work) because I know darn well the day that we don’t will be the day the regulators come in. Companies that think calibration is an optional extra cost are very shortsighted.

I recently had to perform surgery on an optical spectrum analyzer to replace a failing hard disk so it could keep doing its business. Luckily it was the disk itself failing, if it had been the controller board we'd have been in deep doo doo. I probably would have had to fight a dragon to get a replacement.

Load More Replies...I used to work for a printing company on big sheetfed offset presses. This company didn't believe in doing ANYTHING that wasn't production related. No maintenance, period, unless the press wouldn't run. They were literally running them into the ground. I asked what the deal was, and was told that they just planned to replace them with new presses every 5 years. These are 4.5 million dollar machines; and I've worked in shops that keep their presses maintained, and they'll last 30-40 years if taken care of. This just seemed like a huge irresponsible waste of money. You'd rather buy a new machine than spend a max of $500 a week to maintain them? I then asked what happens if business isn't going well when the time comes to replace them? Turns out they stopped paying their suppliers, filed for bankruptcy, tried to keep going for awhile with the old equipment, and eventually the company shut down. Go figure.

A factory I worked in (accountant, not on the floor) there was a huge backwash on maintenance when I started. In the past, old boss had decided to turn down anything that cost money to hike up the proffit. Then he sold the company to a global company. It took a couple of years to get everything back on track. Just as the maintenance departement was up to speed and got everything to run smoothly, the factory shut down due to strategic decissions.

And here’s me keeping a Windows 3.1 box running because it’s the only thing that can connect to and calibrate a piece of kit (it’s a very old piece of kit and modern hardware will not work) because I know darn well the day that we don’t will be the day the regulators come in. Companies that think calibration is an optional extra cost are very shortsighted.

I recently had to perform surgery on an optical spectrum analyzer to replace a failing hard disk so it could keep doing its business. Luckily it was the disk itself failing, if it had been the controller board we'd have been in deep doo doo. I probably would have had to fight a dragon to get a replacement.

Load More Replies...I used to work for a printing company on big sheetfed offset presses. This company didn't believe in doing ANYTHING that wasn't production related. No maintenance, period, unless the press wouldn't run. They were literally running them into the ground. I asked what the deal was, and was told that they just planned to replace them with new presses every 5 years. These are 4.5 million dollar machines; and I've worked in shops that keep their presses maintained, and they'll last 30-40 years if taken care of. This just seemed like a huge irresponsible waste of money. You'd rather buy a new machine than spend a max of $500 a week to maintain them? I then asked what happens if business isn't going well when the time comes to replace them? Turns out they stopped paying their suppliers, filed for bankruptcy, tried to keep going for awhile with the old equipment, and eventually the company shut down. Go figure.

A factory I worked in (accountant, not on the floor) there was a huge backwash on maintenance when I started. In the past, old boss had decided to turn down anything that cost money to hike up the proffit. Then he sold the company to a global company. It took a couple of years to get everything back on track. Just as the maintenance departement was up to speed and got everything to run smoothly, the factory shut down due to strategic decissions.

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

69

13