New Boss Forces 9-5 Work, Ends Up In A Costly No-Win Situation After Worker Maliciously Complies

In a perfect world, management would understand the nature of the work their employees do before implementing rigid policies. But as Reddit user Alwaus‘s post on r/MaliciousCompliance shows, that’s not always the case.

In it, they recalled a time at a manufacturing facility after a change in leadership when the new higher-ups demanded adherence to a strict 9-to-5 schedule.

What followed was an expensive failure, where the insistence on clock-punching turned into a full day’s production shutdown.

A worker was instructed to follow a strict new schedule despite their position calling for different hours

Image credits: astakhovyaroslav (not the actual photo)

But things didn’t go to management’s plan

Image credits: drazenphoto (not the actual photo)

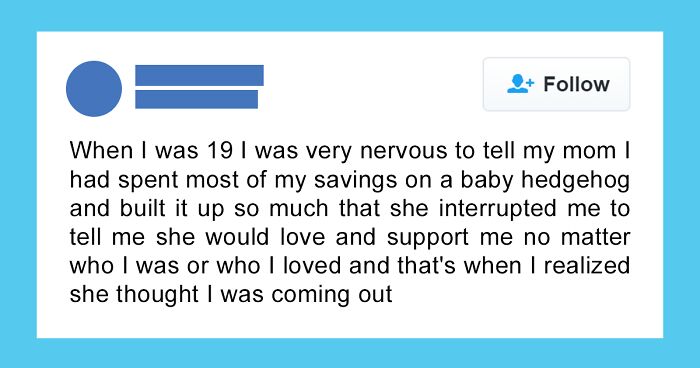

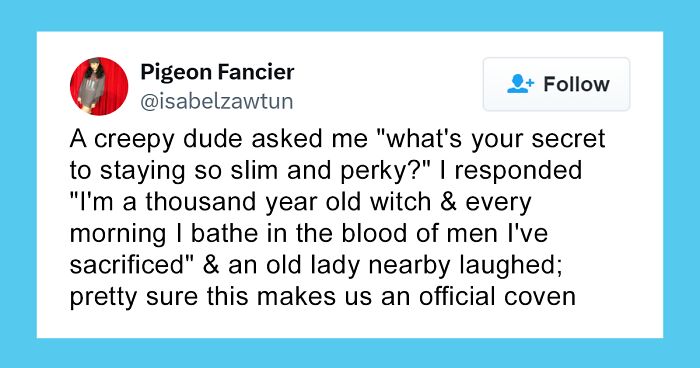

Image credits: alwaus

If you’ve worked at your company for years and are used to getting things done in a particular way, a new superior can add quite a bit of uncertainty

“Getting a new boss can shake up your world,” says Mary Abbajay, president of Careerstone Group and author of Managing Up: How to Move Up, Win at Work, and Succeed with Any Type of Boss. “You have to adjust to a new management style and personality, which is hard if this person is a micromanager, not as friendly as your old boss, or has different priorities. You’re starting from scratch.”

As this story illustrates, problems arise when new bosses have a habit of micromanaging or making unnecessary changes just to stand out. This is, of course, irritating for longtime employees, but Abbajay points out that it’s important to remind yourself to look at things from their standpoint as well.

The boss might be nervous or they might be trying to prove themselves. “They’re also trying to learn their job,” she adds. This is where empathy comes into play. “Give them some grace and space to figure stuff out.”

They’ll likely relax as they settle into the new role and gain a better understanding of the broader organizational context. After all, they might be facing pressure to deliver results, drive cultural change, or deal with turnaround.

However, new leaders often feel like they need to be the smartest person in the room. If they fall into this mindset and become intimidated by someone with more experience in a specific part of the job, they can quickly damage their own career.

Image credits: Tiger Lily (not the actual photo)

As the story went viral, its author provided more details about the situation in the comment section

People have had a lot to say about the entire ordeal

Some even responded with their own similar experiences

Poll Question

Thanks! Check out the results:

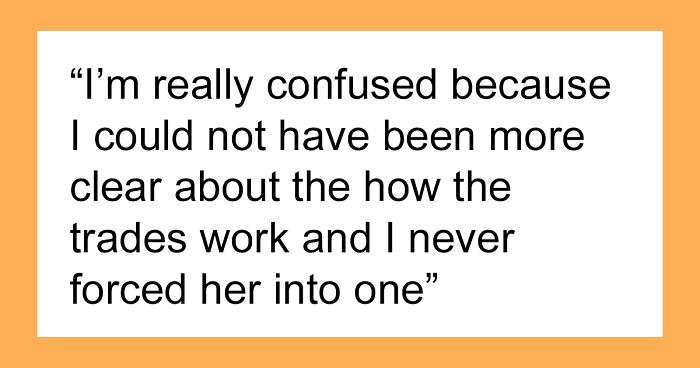

The poll options are not representative of the issues, there should at the least be "its wrong to alter processes to save money before knowing what the cost of changes will be to productivity".

Especially the first option “it’s necessary for productivity” - clearly NOT the case in this story!

Load More Replies...This is part of why I had immediate respect for my boss when he hired on, they wanted him to come in and implement a bunch of new processes, and he was smart enough to wait and see how things went before making any changes AND involved us in the discussions to make sure it worked for everyone

The second comment in the story had me thinking. I have run CNC machines before and they weren't checked daily. I wish OP would've actually answered the question if it was an Aerospace requirement.

It doesn't matter if it's an aerospace requirement if it's part of the company's process. They are certified on that process, whether it's ISO9001 or AS9100 or any of the other ones. They can be audited and have to prove that the process was done as written in their process plan. Since these parts are going into production type items (ie: vehicles, planes, etc) there are a ton more requirements that are more than just tightening some material in a vise or screwing it down to a table.

Load More Replies...The poll options are not representative of the issues, there should at the least be "its wrong to alter processes to save money before knowing what the cost of changes will be to productivity".

Especially the first option “it’s necessary for productivity” - clearly NOT the case in this story!

Load More Replies...This is part of why I had immediate respect for my boss when he hired on, they wanted him to come in and implement a bunch of new processes, and he was smart enough to wait and see how things went before making any changes AND involved us in the discussions to make sure it worked for everyone

The second comment in the story had me thinking. I have run CNC machines before and they weren't checked daily. I wish OP would've actually answered the question if it was an Aerospace requirement.

It doesn't matter if it's an aerospace requirement if it's part of the company's process. They are certified on that process, whether it's ISO9001 or AS9100 or any of the other ones. They can be audited and have to prove that the process was done as written in their process plan. Since these parts are going into production type items (ie: vehicles, planes, etc) there are a ton more requirements that are more than just tightening some material in a vise or screwing it down to a table.

Load More Replies...

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

51

21