Volunteers Made A Pop-Up Factory To Mass Produce Ppe For Healthcare Workers. They Did It In A Month.

Three friends, all engineers, had an idea that they could help during the COVID-19 pandemic. They discussed different technologies and settled on face shields. They determined that every part of their process would be transparent and open source, to help groups in other places similarly affected by the pandemic.

They had no space and limited materials.

That was exactly one month ago. Today, thanks in no small part to the support of 1partCarbon, they have a functioning factory that produces 3000 face shields per day and delivers them free to local hospitals and healthcare workers.

They went from an idea to mass production in one month.

Today they are the Edinburgh Shield Force.

A team of about 40 people work behind the scenes to keep the factory running.

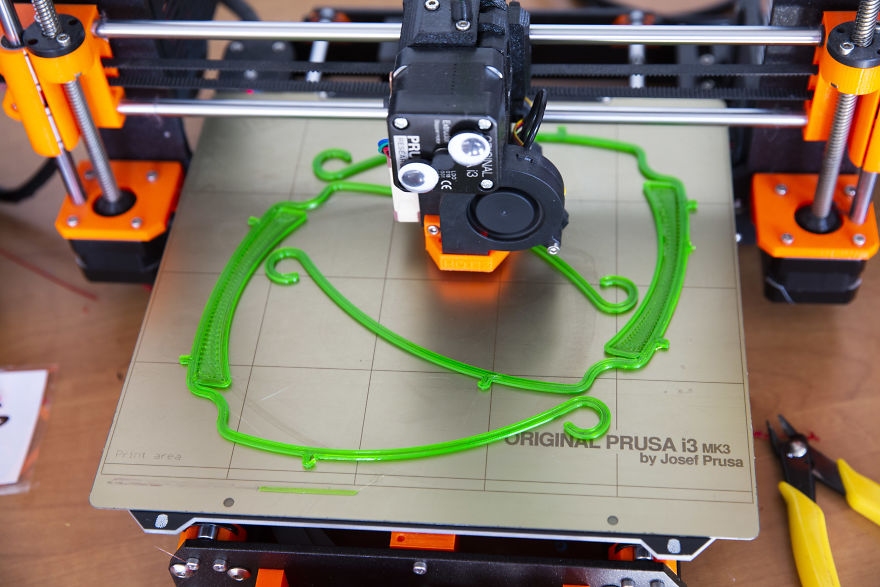

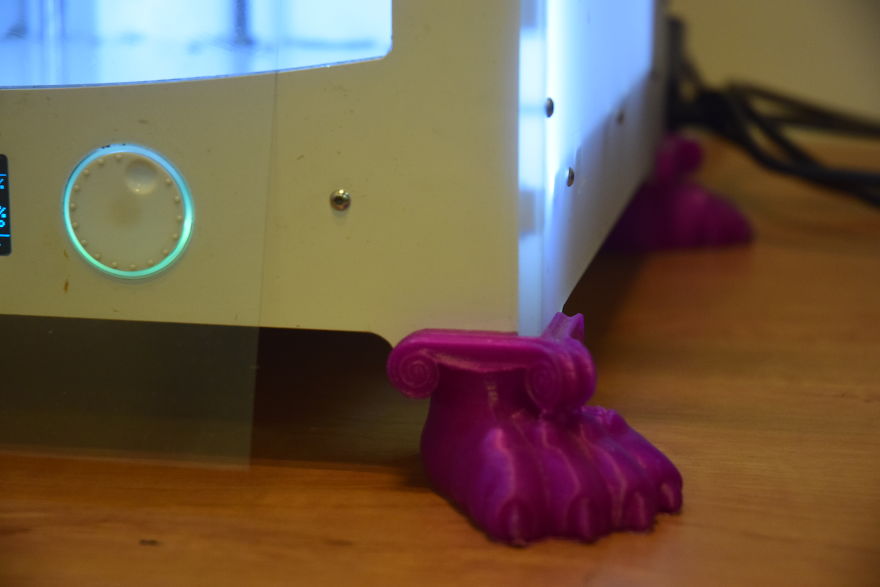

A fleet of fifteen 3D printers churn out visors 24/7.

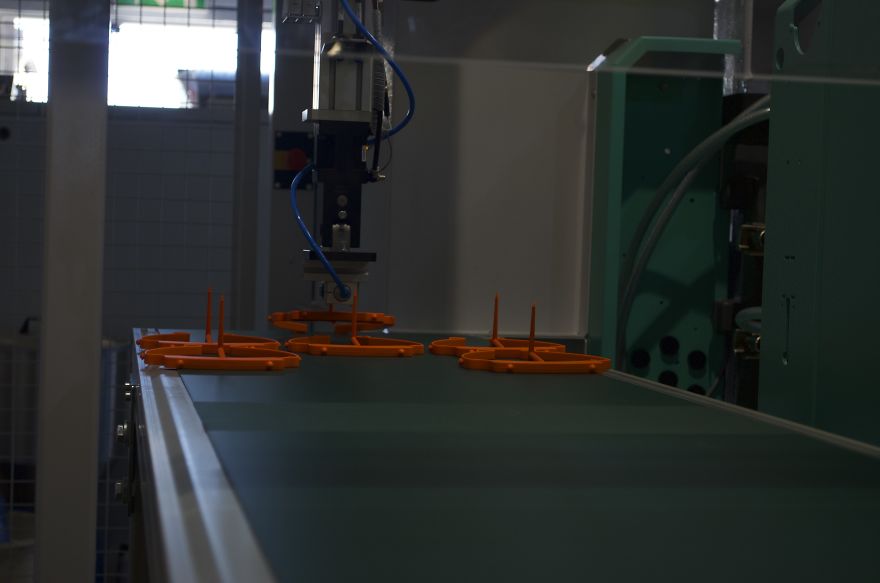

An injection moulder produces 2000 visors daily.

The factory is staffed by trained volunteers who come from the community to manufacture, assemble and package 3D printed and injection moulded face shields.

They also produce foam face shields, which require little technology and can be produced by anyone with the ability to cut foam .

They have two goals :

1.) To provide PPE to as many frontline healthcare workers as possible.

2.) To be put out of business.

All of the information about their processes- including gcode and instructions- is up on their website.

https://www.edinburghems.com

More info: crowdfunder.co.uk

The original design was made by 3DVerkstan, a Swedish additive solutions company.

Shield Force engineers tweaked the design and figured out how to make the 3D printers print continuously. This allows the printers to produce many more visors and minimizes the need for human contact.

An Ultimaker automatically removing a printed visor

A box of 3D printed visors that were printed automatically overnight

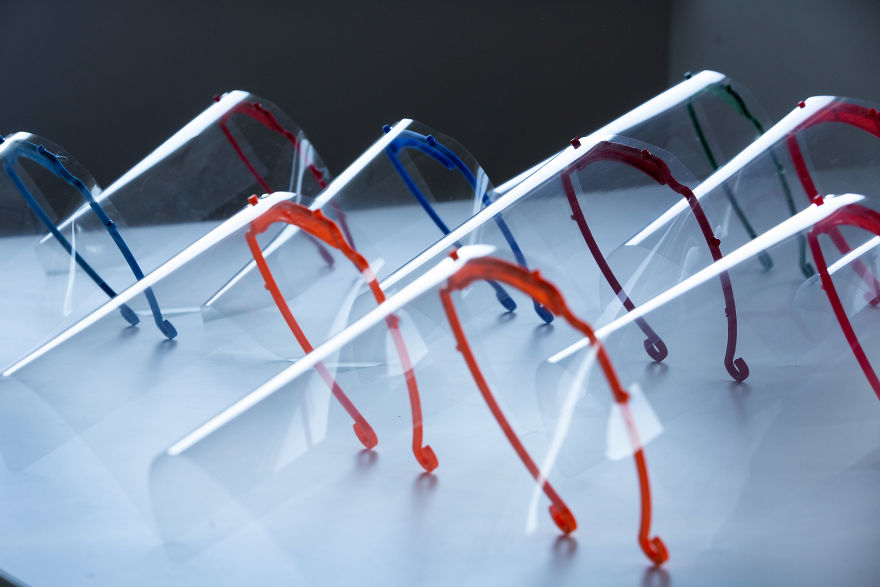

3D printed face shields ready for testing

Healthcare workers wearing the first version of ESF’s injection moulded face shields.

Volunteers packaging 3D printed face shields

Edinburgh Shield Force

3D printed feet on a 3D printer. Yes, it printed its own feet.

Testing a face shield through the medium of dance.

Packaged face shields ready for packing!

How to package face shields cleanly using a sealing machine

Mastering the foam visor

Testing a foam visor

An injection moulded face shield in action!

Injection moulded visors hot off the machine

903views

Share on Facebook

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

4

0