The Evolution Of Clothing Manufacturing Technology: From Handmade To High-Tech

Clothing manufacturing has evolved incredibly over the years, thanks to advanced technology. Since designing clothes through hand tools and manual labor, we have entered the era of automation and robotics in clothing manufacturing.

Using high-tech tools and machines has made the production process faster, more cost-effective, and more efficient.

Through this blog, we will explore the evolution of clothing manufacturing technology, the impact of automation, robotics, AI, and machine learning on production processes, and future trends and innovations in the industry.

More info: usaclothingmanufacturers.com

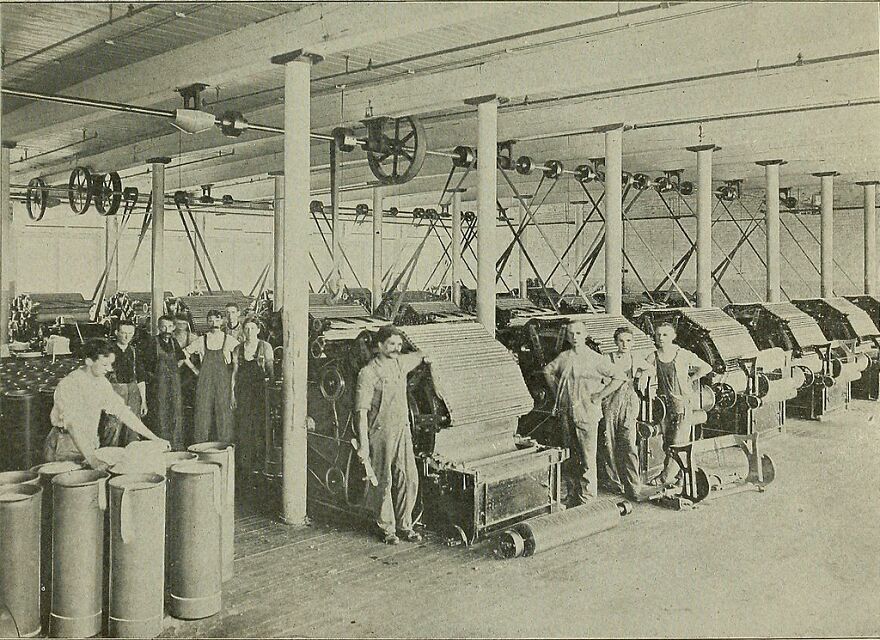

18th Century

The first significant change in clothing manufacturing technology came in the 18th century, at the time of the invention of the spinning jenny. The machine could spin multiple threads simultaneously, leading to less manual labor and more productivity.

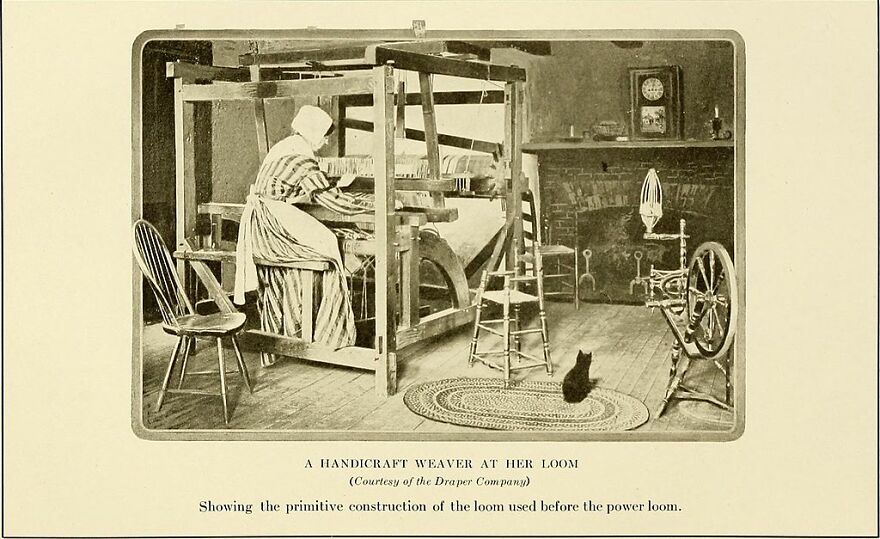

19th Century

In the 19th century, the industrial revolution estimated more developments, like introducing the power loom, which could weave fabric much faster and more efficiently. As the demand for clothing increased, the manufacturing industry grew rapidly, putting pressure on manufacturers to develop more advanced and efficient tools.

Automation

Technology has played a huge role in speeding up the production process, improving quality, and making clothing manufacturing more efficient and cost-effective. The clothing industry lies in embracing newer and cutting-edge technologies.

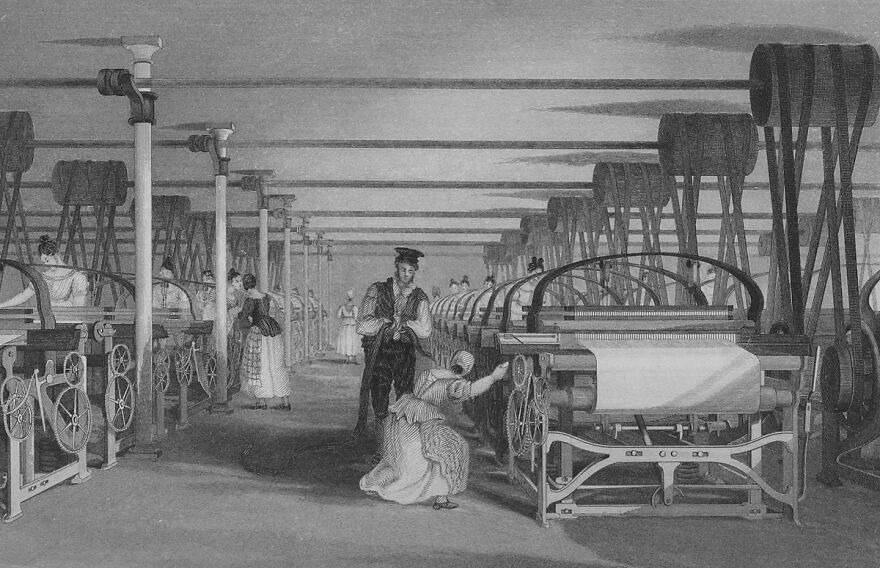

Industrial Revolution

In the 21st century, the bulk clothing manufacturing industry has become much more technology-driven. Automation and robotics have taken over many labor-intensive processes like cutting, stitching, and assembling, ensuring the production process is faster, more accurate, and less expensive.

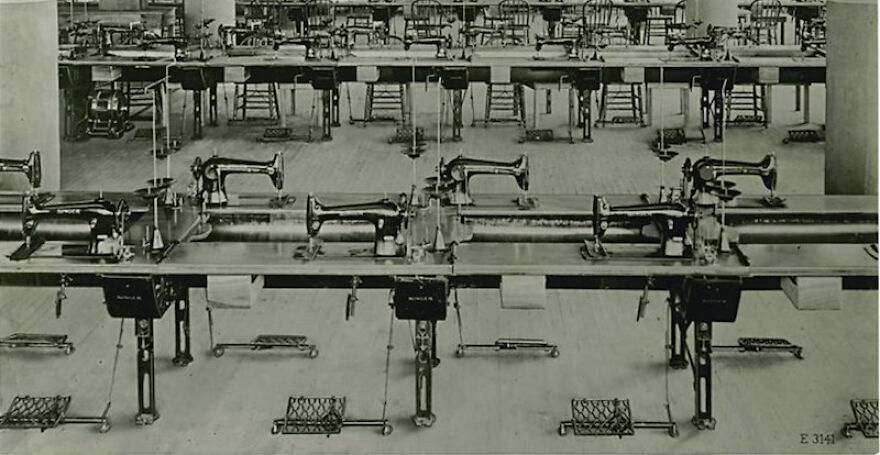

20th Century

Advanced Automation

Image credits: www.fitnessclothingmanufacturer.com

Machines can churn out thousands of garments daily, reducing the time required to manufacture clothes. With advancements in 3D printing, manufacturers can also design and create garment prototypes quickly and efficiently.

Robotics & AI

The synergy of AI and machine learning in clothing manufacturing has further revolutionized the industry. Intelligent machines can now analyze data to predict consumer demand and forecast sales, aiding inventory management. Machine learning algorithms can analyze design patterns, colors, and consumer preferences to create customized clothing that meets consumer preferences. Using AI in quality control ensures that garments meet specific standards and are defect-free.

In the future, the clothing manufacturing industry will embrace newer and cutting-edge technologies. Virtual 3D samples and digital twinning will help manufacturers create realistic garment simulations that can help reduce the need for physical samples. Sensors and wearable technology will enable the production of smart clothing that can monitor health and fitness data, temperature, and humidity and even track skin resistance and muscle movement.

439views

Share on Facebook

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

13

0