Guy Builds A Manly “Christmas Story” Leg Lamp And Here’s How He Did It

Learn to how build your own (manly) “A Christmas Story” leg lamp by watching this DIY tutorial made by woodworker Jackman Works.

This leg is an exact full scale model of Jackman Works’ own leg. The leg and base are made from maple butcher block scraps from previous projects. The lamp shade is welded from scrap lengths of rebar and wrapped in pleather attached using paracord that looks like Carolina®’s boot laces.

The Carolina® ‘ELM’ Logger boot is attached using a threaded brass lamp rod through the entire leg with a nut on both ends. There are also a couple of screws into the toe of the boot/foot.

More info: jackmanworks.com

Woodworker Jackman Works created a lamp in an image of his own leg

It all started by taking photos of his leg

He got a photo from all sides and then brought them into GIMP to edit it down to just the silhouette of his leg. Then it was used to make a template and print it out full scale

Then the materials had to be gathered

Maple butcher block for the leg, lamp parts, rebar for the shade, and a log for the fire.

The maple butcher block is cut down roughly to size to make a sort of topographical layering

Less material needed towards the bottom of the leg and a few more layers needed for the extra thickness at the top.

The leg is traced out onto one of the tall pieces and then cut down to size on the bandsaw

I can then use the first piece as a template to trace out the rest of the pieces.

He cut out the inside of the center pieces where he carved down from the outside

This starts the process of taking off some weight of the leg. Then he spread glue on each layer and made a leg sandwich. The leg is clamped to keep it together.

After letting the glue dry overnight he took the leg blank out of the clamps. With the bandsaw he was able to make this piece the right shape in 2 dimensions and now it needed to be established in the 3rd dimension

He marked the lines on both sides, he needed to connect each side in order to establish the shape of the left and ride side of the leg. Then it was time for some power carving

He rounded things over to give this thing a real leg shape

He drew the rough shape to use as a guide.

And soon it looked like a real leg

He founnd the joint that holds the piece of paper and popped that apart with a chisel and hammer in the top of the leg

This allowed him to gain access to the inside of the leg for hollowing.

Each side of the joint is sanded down

Then he power carved out the inside of each piece to reduce weight and to establish a route from top to bottom where the wire will run up to the light. Once he was satisfied with the inside, he glued and clamped the 2 halves back together.

With the glue dry, the final shaping was done by just sanding through the grits

The passageway from the top to bottom of the foot is completed by drilling a hole in the center of the new top leg plate and in the bottom of the foot

For the bottom plate, he cut down another piece of the maple butcher block scraps to a circle slightly larger than the boot and center the boot in place

He pushed the conduit through the leg to mark the plate so he can drill a hole through to run the wire

The leg was coated with Waterlox Original to get some finish on the wood

After 3 coats with a high grit sanding between coats and then some really high 600 grit to knock off any little fuzzies after the final coat

assembly began

The threaded rod is cut down to the right height with a hacksaw and then the top of the lamp is threaded on

Then he attached the wires to the screws and installed the top of the lamp in place

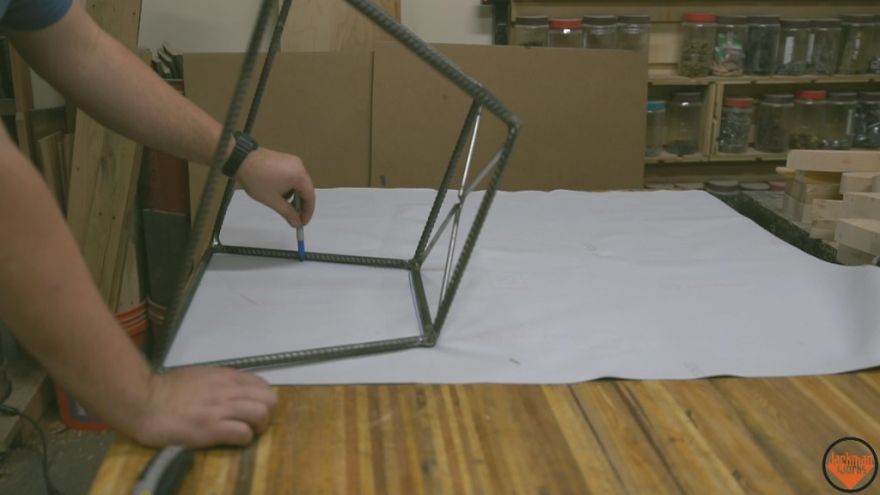

The top for the lamp is wielded

Once the corners were ground down smooth, it was time to get the actually sides of the shade in place

He traced out each side of the lamp on his sheet of pleather to get the right shape.

Then the material was cut and the holes around the perimeter of each piece were punched

To lace these in place around the metal frame he uses some paracord that matched the color of the boot laces best

He looped it over and over along the top and bottom of each side panel and then did the same thing running up each of the 4 corners pulling everything nice and tight.

And once the top was on, the lamp was finished

Building “A Christmas Story” Leg Lamp

13Kviews

Share on FacebookI was relieved to learn this was about woodworking rather than taxidermy.

I feel like the lampshade should look more like a kilt to look truly manly. I know the movie version has the fringe, but as long as we're going manly here, um what kind of men's garment looks like that with the fringe?

Yes a kilt shade would make this amazing! A la Jamie Fraser from Outlander for me please! hahaha

Load More Replies...Guy at a pub asked why I was looking at him in a strange way. "I am trying to imagine what you would look like as a standard lamp" He thinks I'm weird. His band mates loved how I was the only female not drooling over him (his comments to other females caused me to think of a use for a nice body without his brain getting in the way)

I was relieved to learn this was about woodworking rather than taxidermy.

I feel like the lampshade should look more like a kilt to look truly manly. I know the movie version has the fringe, but as long as we're going manly here, um what kind of men's garment looks like that with the fringe?

Yes a kilt shade would make this amazing! A la Jamie Fraser from Outlander for me please! hahaha

Load More Replies...Guy at a pub asked why I was looking at him in a strange way. "I am trying to imagine what you would look like as a standard lamp" He thinks I'm weird. His band mates loved how I was the only female not drooling over him (his comments to other females caused me to think of a use for a nice body without his brain getting in the way)

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

118

19