Boeing, which has been repeatedly questioned in recent times over its safety standards, is further embroiled in controversy following a recent Federal Aviation Administration (FAA) report.

Dozens of problems were found at Boeing-owned facilities, and one of the company’s key suppliers was found using a hotel key card and dish soap to fit a door seal.

The revelations came about after the FAA conducted a probe, which was initiated after a door panel blew off a 737 Max 9 during an Alaska Airlines flight in January.

The results of FAA’s six-week audit raised serious concerns about the quality control practices at both Boeing and one of its key suppliers, Spirit AeroSystems.

“Dozens of problems” were found by U.S. air safety regulators, and Boeing failed 33 tests out of 89 product audits, the New York Times reported.

The revelations came about after the FAA conducted a probe initiated after a door panel blew off during an Alaska Airlines flight

Image credits: Maria Tyutina / Pexels

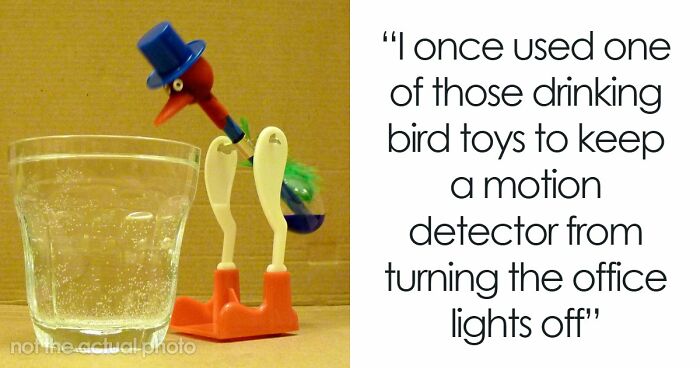

Spirit AeroSystems — responsible for making the body of the 737 Max jets for the aerospace giant — failed 7 out of 13 product audits conducted by the FAA. While conducting the probe, FAA auditors witnessed workers of Spirit AeroSystems using a hotel key card to check the seal on a door on one occasion. They also reportedly saw some of the mechanics applying liquid Dawn soap to a door seal as a lubricant in the fit-up process and then using a wet cheesecloth to wipe away the dish soap.

When asked about their processes, the mechanics were “vague and unclear on what specifications/actions are to be followed or recorded by the mechanic,” the FAA report said.

Boeing failed 33 tests out of 89 product audits, the FAA report said

Image credits: Ahmed Muntasir / Pexels

Spirit AeroSystems said they are “reviewing all identified nonconformities for corrective action.”

Boeing also acknowledged the FAA findings and said they are willing to make changes to improve quality.

“We have a clear picture of what needs to be done. Transparency prevailed in all of these discussions,” Boeing said in a statement. “Boeing will develop the comprehensive action plan with measurable criteria that demonstrates the profound change that Administrator [Michael] Whitaker and the FAA demand. Our Boeing leadership team is totally committed to meeting this challenge.”

Boeing said their leadership is willing to make changes to improve quality

Image credits: Skitterphoto / Pexels

The terrifying ordeal of the door panel blow-out aboard the Alaska Air flight also sparked a criminal probe into Boeing by the Justice Department.

“These planes shouldn’t be allowed to fly,” someone commented

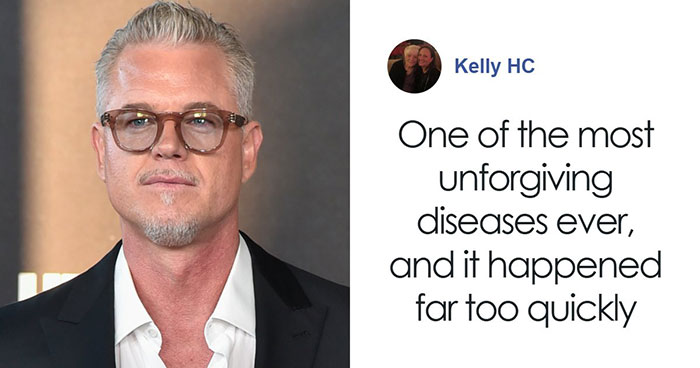

One of the comments referenced John Barnett, a former Boeing employee turned whistle-blower who was found dead in his truck of a "self-inflicted wound" the day before he was to return to court to continue giving his testimony. This happened yesterday or the day before, I believe.

If the process diagram calls out a "0.75mm plastic shim" for inspection, and hotel key cards are 0.75mm thick, then I fail to see a problem with that. Similarly, dish soap is a neutral water-based lubricant, widely used in installing rubber parts. Naturally this is a problem if it wasn't called for in the document, not a problem in itself.

Exactly true - though the precise plastic in the shim could easily be important- nothing wrong with dish soap- but everybody in the process needs to be informed and on board. They weren't

Load More Replies...This is what chasing profits over safety inevitably looks like. Having said that, the key card and soap don't really read like failed processes as both could conceivably get the exact results that meet best fit on the component parts, the devil is in the detail...would the soap residue degrade the seal over time? Is the solution too viscous or too watery to act correctly for the task? We don't know but maybe the engineers do know.

One of the comments referenced John Barnett, a former Boeing employee turned whistle-blower who was found dead in his truck of a "self-inflicted wound" the day before he was to return to court to continue giving his testimony. This happened yesterday or the day before, I believe.

If the process diagram calls out a "0.75mm plastic shim" for inspection, and hotel key cards are 0.75mm thick, then I fail to see a problem with that. Similarly, dish soap is a neutral water-based lubricant, widely used in installing rubber parts. Naturally this is a problem if it wasn't called for in the document, not a problem in itself.

Exactly true - though the precise plastic in the shim could easily be important- nothing wrong with dish soap- but everybody in the process needs to be informed and on board. They weren't

Load More Replies...This is what chasing profits over safety inevitably looks like. Having said that, the key card and soap don't really read like failed processes as both could conceivably get the exact results that meet best fit on the component parts, the devil is in the detail...would the soap residue degrade the seal over time? Is the solution too viscous or too watery to act correctly for the task? We don't know but maybe the engineers do know.

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

13

4