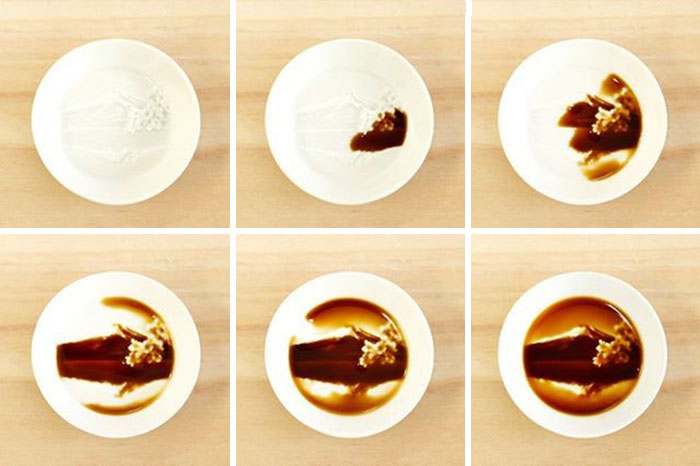

After Pouring Soy Sauce Into These Plates, Entire “Hidden Paintings” Appear

3D printing has been around for a while now. From toucan beaks to houses, we’ve already created some pretty cool stuff using this technology. However, we’re just scratching the surface of its capabilities. And while some are pushing it forward, trying to produce 3D-printed food, a Japanese design studio has decided to create something where you could put it.

More info: redestu.buyshop.jp | Instagram

For a modest amount of ¥ 1,080 ($10), ReDeStu are selling porcelain soy sauce dishes that “reveal” a painting once you fill them up. So far, the series consists of Japanese national symbols (Mount Fuji, Itsukushima Shrine) and cute kitties and puppies.

Interestingly, soy sauce is thought to have originated from a Chinese product called “chiang” over 3,000 years ago. It first came to Europe around the 1600s through Dutch and Japanese trading. The word “soy” is derived from the Japanese word for soy sauce, “shoyu.”

Today, there are many different types of soy sauce. They can be grouped based on their production methods, regional variations or color and taste differences. The traditional soy sauce is made by soaking soybeans in water while roasting and crushing the wheat. Then the soybeans and wheat are mixed with a culturing mold, for example, Aspergillus, and left for two to three days to develop. Later, water and salt are added and the entire mixture is left for fermentation anywhere for five to eight months, though some types may age longer.

When 3D printing first came out the printers were too expensive to buy just for fun. These days, though, 3D printing has become a trend and more and more manufacturers produce 3D printers, meaning they have become more accessible to both businesses and regular people.

“If you examine the 3D printing market today, you will find tons of 3D printers brands that offer different features,” All That 3D wrote. “Some are packed with powerful functionalities and are offered at a much higher price. Others offer the basic functions and are sold at a much cheaper price. However, in the coming years, you can expect more powerful 3D printers at a very affordable price.”

3D printing first used plastic as a material, but as the technology progresses more materials are being utilized. Now, as you can see, you can 3D print using things like ceramic, gold, silver, titanium, gypsum and even biological substances.

Here’s a video of what happens when you pour in the sauce

People had a lot to say about these designs

Explore more of these tags

These don't look like a 3D printed object, the look like they're cast in ceramic. It's like they made a mold utilizing 3-D printing, then cast from that. Very cool though.

Ah, I just went to their website and this is exactly what they're doing "The Photoreal Soy Sauce Dish-enman-series uses a high-definition 3D printer to create a prototype, which is then cast into a mold. It is made of bright white white porcelain so that the pattern is clear, and the glaze is made as thin as possible so that the small pattern does not disappear. "

Load More Replies...These don't look like a 3D printed object, the look like they're cast in ceramic. It's like they made a mold utilizing 3-D printing, then cast from that. Very cool though.

Ah, I just went to their website and this is exactly what they're doing "The Photoreal Soy Sauce Dish-enman-series uses a high-definition 3D printer to create a prototype, which is then cast into a mold. It is made of bright white white porcelain so that the pattern is clear, and the glaze is made as thin as possible so that the small pattern does not disappear. "

Load More Replies...

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

405

27