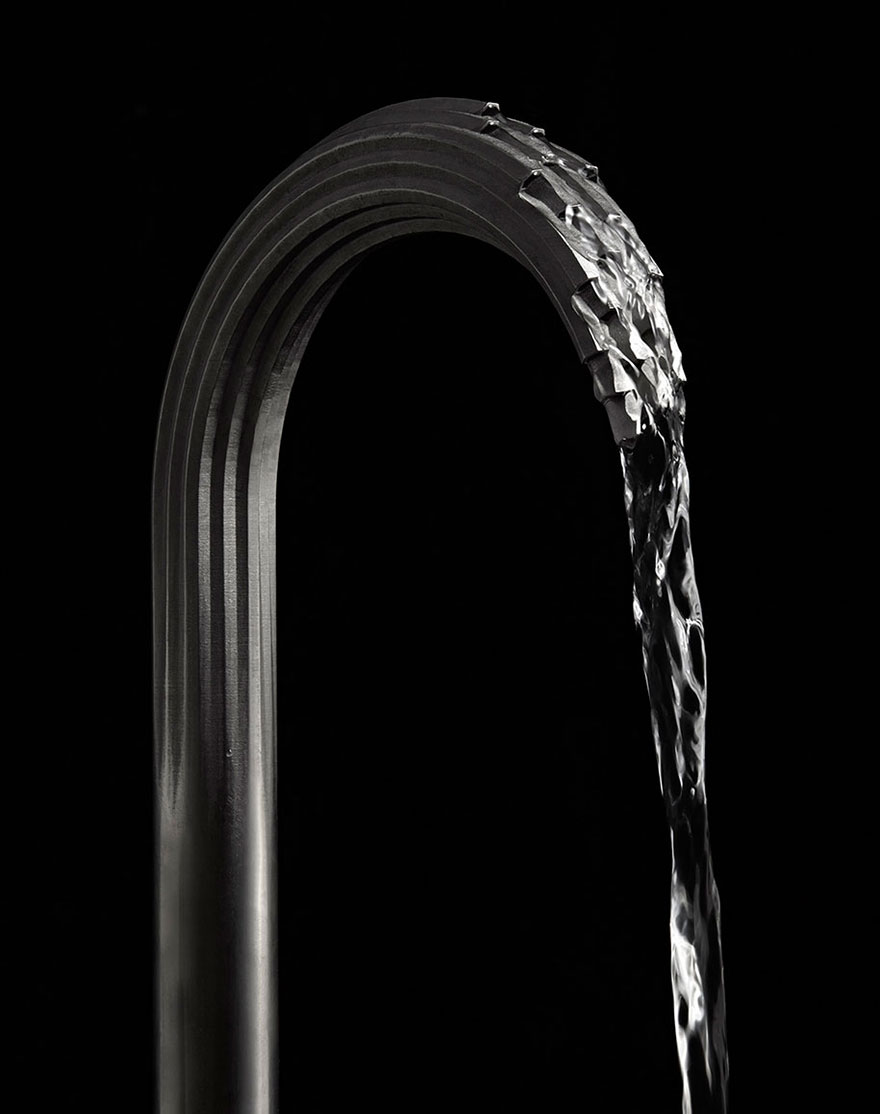

Impossible 3D-Printed Faucets Show The Amazing Possibilities Of Metal Printing

By using an older form of 3D printing in a novel way, American Standard, a U.S. faucet manufacturer, has created a collection of seemingly impossible bathroom faucets that are works of art.

Selective laser sintering is a form of 3D printing that involves using powerful lasers to heat and fuse metal powder to produce parts or shapes that would be difficult or impossible to create with traditional methods. The process has been around since the 1980s, and 3D printing has been used to design and prototype faucets for ages, but American Standard claims that these are the first ready-for-market faucets produced by printing with metal. These exclusive faucets, however, will not come cheap; “The estimated retail price will be somewhere between $12,000 – $20,000.”

The angular geometric faucet is especially interesting. It was created to mimic “the experience of water. The water is presented to the user as a stream bouncing on rocks in a riverbed… the team used Computational Fluid Dynamic (CFD) technology to adjust each of the 19 waterways to achieve the proper effect.”

More info: americanstandard-us.com (h/t: designboom)

146Kviews

Share on FacebookExplore more of these tags

Who created these taps never clean a bathroom in his entire life.

I really liked these taps until you said that. You spoiled it but you're right. Darn.

Load More Replies...Who created these taps never clean a bathroom in his entire life.

I really liked these taps until you said that. You spoiled it but you're right. Darn.

Load More Replies...

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

165

23